Many clients will specify that they want their tray washers (and other washing systems) to wash their products, but will also ask for the products to be dry on exit from the machine too. Now it may sound an odd question, but one should ask how dry is dry?

The washing of products is a straightforward and effective process, but not many people realise the cost implications of an air knife or drying system, and the potential difficulties that they can present.

It is incorrect for any washing machine supplier to refer to their basic Air Knife section as ‘dryers’. The term drying implies that there is no presence of residual water on any of the washed components when exiting the system. As most manufacturers will know, this process is extremely difficult with air knives alone.

Air Knife Systems

An air knife is a blade, supplied with air via a centrifugal blower, side channel blower (or something similar), that is positioned around the washed product in order to remove excess water from the surfaces prior to exiting the machine. The blade creates a wiping effect over the product, similar to the final stage of a commercial car wash, pushing the water to the rear or the product as it passes, and blowing it back into the machine. This clears the product of water and minimises water carryout from the system. Easy you would think, but not necessarily.

In order to maximise the effect of the knife, the distance from the product should be minimised. As with jetting, the effectiveness reduces the further it is away from the surface. This can be a particular problem with items such as crates and baskets where the knife is the height of the container, away from the internal surface. Although water will be blown off the surface, it’s not very effective. However, with the correct Air Knife design and the correct blower, most if this can be minimised.

Air Knife Designs

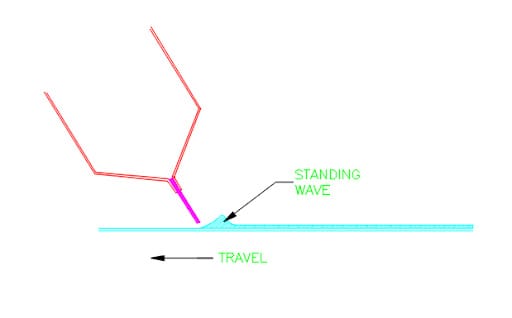

Flat surfaces are ideal for air knife effectiveness, as a standing wave can be created and maintained over the smooth plane (see image below). However, unless you are ‘drying’ baking sheets or shallow trays, invariably most crates and plastic containers have strengthening ribs on the outer surfaces, which break up the standing wave and make the air knife less effective.

Most of the water can be removed from these areas, but due to the strengthening ‘ribs’, complete drying is almost impossible with air knives alone. Generally about 6-8 grams of residual water can be achieved cost effectively, depending on process speed and container design. Following this, heat is required to evaporate the residual liquid.

The issue with plastic trays is that they give up heat fairly quickly, so the surfaces of the tray cool rapidly and therefore any heat used in the knife itself is minimised (you only need to look at plastic utensils in most domestic dishwashers to see the lack of surface evaporation).

Heat can be introduced into the airflow to the knife by various means and can make a slight improvement on the level of dryness. The energy required to do this, when offset against the improvement gain can be costly. However it can help maintain a higher ambient temperature within the Air Knife section of the machine, increasing the evaporation or ‘flash drying’ effect.

An air knife blower and pipework can generate up to 25-30°C without adding heat due to friction and compression of the air within the system.

Heat Tunnel Systems

In order to offer complete dryness, a heat tunnel can be employed. This acts as a travelling oven, maintaining a high ambient temperature, and employing directional nozzles to assist in accelerating the evaporation of the water from the product surfaces. The trays, when subjected to this type of drying, should not exceed the suppliers specified working temperature (generally around 60°C) to prevent distortion or damage, so careful control of the system is paramount.

As with both the Air Knife and Heat Tunnel systems, the process speed and crate design will influence the dryness achieved, and a compromise may be required, due to space constraints, available budget and energy usage.

So if you are interested in purchasing an industrial washing machine, please ask yourself how dry do your containers really need to be? If you are using them immediately or for dry goods, then yes, dry! But if you are allowing them to stand for a short period of time, will an air knife system be sufficient?

Get In Touch

Unitech Washing Systems have designed, built and supplied various systems with air knives and heat tunnels successfully for many of our clients, so please do not hesitate to contact us for further information on any of our washing equipment.