In the world of industrial and commercial washing, drying is just as important as cleaning. After items are washed, any leftover water can cause problems. That’s where an air knife drying system comes in. But what actually is it and what can be achieved? Let’s find out.

Understanding Air Knife Drying Systems

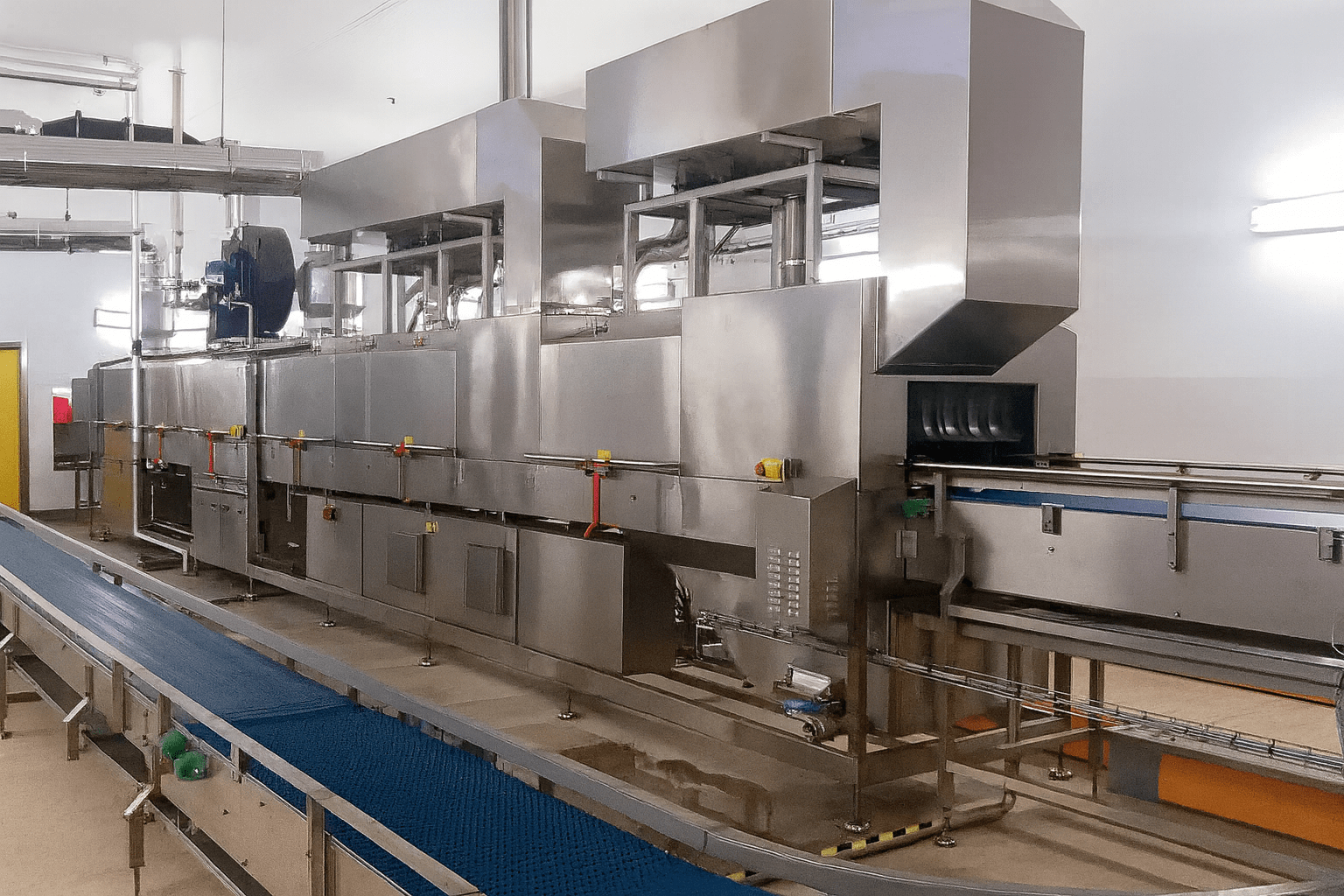

An air knife drying system uses high velocity air to remove water from items as they exit the wash cycle. The ‘air knife’ itself is a slim, elongated blade connected to a centrifugal blower or similar device. As products pass by, the knife directs a controlled stream of compressed air across the surface, pushing water away quickly and evenly.

This method works much faster than traditional drying techniques, making it ideal for high volume production lines where efficiency matters.

Does It Completely Dry the Item?

Not always. An air knife drying system removes most surface water by creating a strong ‘wiping’ effect over the product, similar to the final stage of a car wash. For situations where total dryness is essential, combining air knife systems with a heat tunnel is the most effective solution.

Why Are Air Knife Systems Used in Industrial and Commercial Washing?

In industries where items must be washed and dried quickly, an air knife drying system is the perfect solution. It removes water without contact, reducing the risk of contamination or damage. By removing surface water, it also prepares products for the next stage of production, whether that’s packing, coating, or assembly.

In Unitech’s washing systems, air knife blowers are positioned after the wash and rinse stages. This setup makes sure products pass through the airflow immediately after washing.

Many of our clients in food processing, manufacturing, and engineering choose this option because it saves both time and energy.

The Benefits of Using Air Knife Drying

Air knife systems offer several key advantages for industrial washing applications:

- Faster drying – High-speed air removes water almost instantly.

- Energy savings – Air knives use less energy than heated drying alone.

- Improved hygiene – Less moisture means fewer risks of contamination.

- Better production flow – Reduces delays between washing and the next processing step.

Air Knife Drying vs Traditional Drying Methods

Traditional drying often relies on heated air, fans, or absorbent materials. While these methods can still work, they are usually slower and less efficient. Air knife systems, on the other hand, use focused streams of air to remove water instantly without relying on high temperatures.

This makes them ideal for sensitive items or products where heat could cause damage.

See One in Action

Why Choose Unitech Washers for Air Knife Solutions

Unitech Washers has years of experience designing industrial washing systems that meet the needs of modern production lines. We offer air knife blowers as an optional feature to make your washing process faster and more efficient.

Our engineers design each system with precision, tailoring the solution to your products, production space, and speed requirements. Whether you need a compact washer or a large scale automated line, we integrate air knife drying technology where it delivers the most value.

Talk To Us Today

If your current drying process slows down production or leaves items damp, an air knife system may be the solution.

If you want to improve your production process, simply get in touch with us on 01543 224608 and we’ll be happy to discuss your needs. Or email us at washers@unitech.uk.com. Our team can guide you through the best solutions for your business and show you how an air knife drying system can make a real difference.