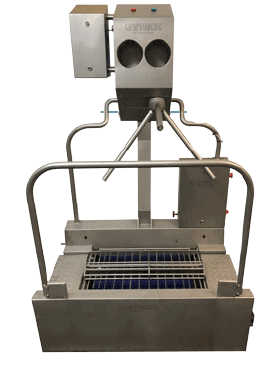

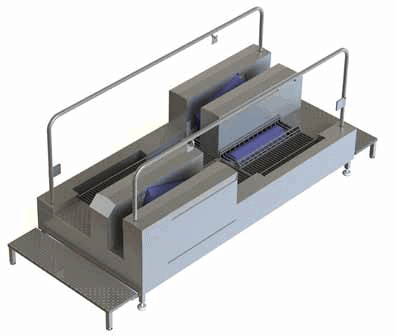

At Unitech Washers, we know a thing or two about keeping working environments sterile and safe. It’s the core of our business. So if you need to manage how dirt enters and exits your food production areas – you’re in the right place. Without throwing too much information at you, we’ll explain the key benefits of boot washers and why we think they’re a great investment.

Top 5 Benefits of Boot Washers

1. Improved Hygiene

Let’s start with the obvious one first. Afterall, maintaining a high standard of hygiene is absolutely paramount in food processing facilities.

Boot washers provide an efficient, automated cleaning solution that helps remove dirt and grime that could be carried into the facility on workers’ footwear. Our washing systems use high pressure water jets and disinfectants to ensure that no unwanted germs make their way past your doors.

2. Preventing Cross Contamination

One of the major causes of food poisoning from food production environments is cross contamination. This occurs when harmful bacteria, allergens, or other pathogens are transferred from one surface to another, potentially compromising food safety.

For example, a worker in a meat processing plant finishes a shift handling raw poultry and moves to a packaging area where cooked products are sealed. If the facility lacks proper hygiene protocols, the bacteria can be easily carried and deposited from the workers shoes into the packaging area. Other workers (or even a piece of equipment) could pick up the bacteria and come into contact with the cooked products, contaminating them.

By cleaning the boots of employees as they transition between different zones, boot washers eliminate harmful particles and reduce the risk of contaminating food products.

3. Protect Your Brand Reputation

So what are the consequences if a boot washer isn’t installed?

Above all, it can impact people’s health. Additionally, there could be serious legal repercussions for the business too.

A boot washing station will ensure that your facility keeps a strong barrier against these risks, safeguarding your products, your brand reputation, and ultimately, public health.

4. Compliance with Industry Regulations

In the UK and Europe, food safety regulations are rigorous and designed to ensure the highest standards of hygiene and safety in food processing environments. This includes the management of personal hygiene and the use of appropriate cleaning and disinfecting equipment, such as boot washers, to prevent the introduction of contaminants into critical areas.

5. Increased Productivity

Finally, by opting to choose an automated boot washer, you can significantly reduce the time employees spend on manual boot cleaning. This allows workers to move quickly and safely into production areas, boosting overall operational efficiency.

Our customers report noticeable improvements in workflow and reduced downtime related to hygiene maintenance.

Buy a Boot Washer from Unitech

Unitech has a proven track record of delivering boot washers that meet and exceed customer expectations. Many businesses across various industries have benefited from our washers, making them a reliable choice for your cleaning needs. From installation to maintenance and troubleshooting, Unitech’s team of experts is ready to assist you every step of the way.