If you have ever wondered how delicate parts come out perfectly clean without scrubbing or harsh chemicals, the answer is often ultrasonic cleaning. It may sound complex, but the idea is actually simple. Let’s find out.

The Basic Idea Behind Ultrasonic Cleaning

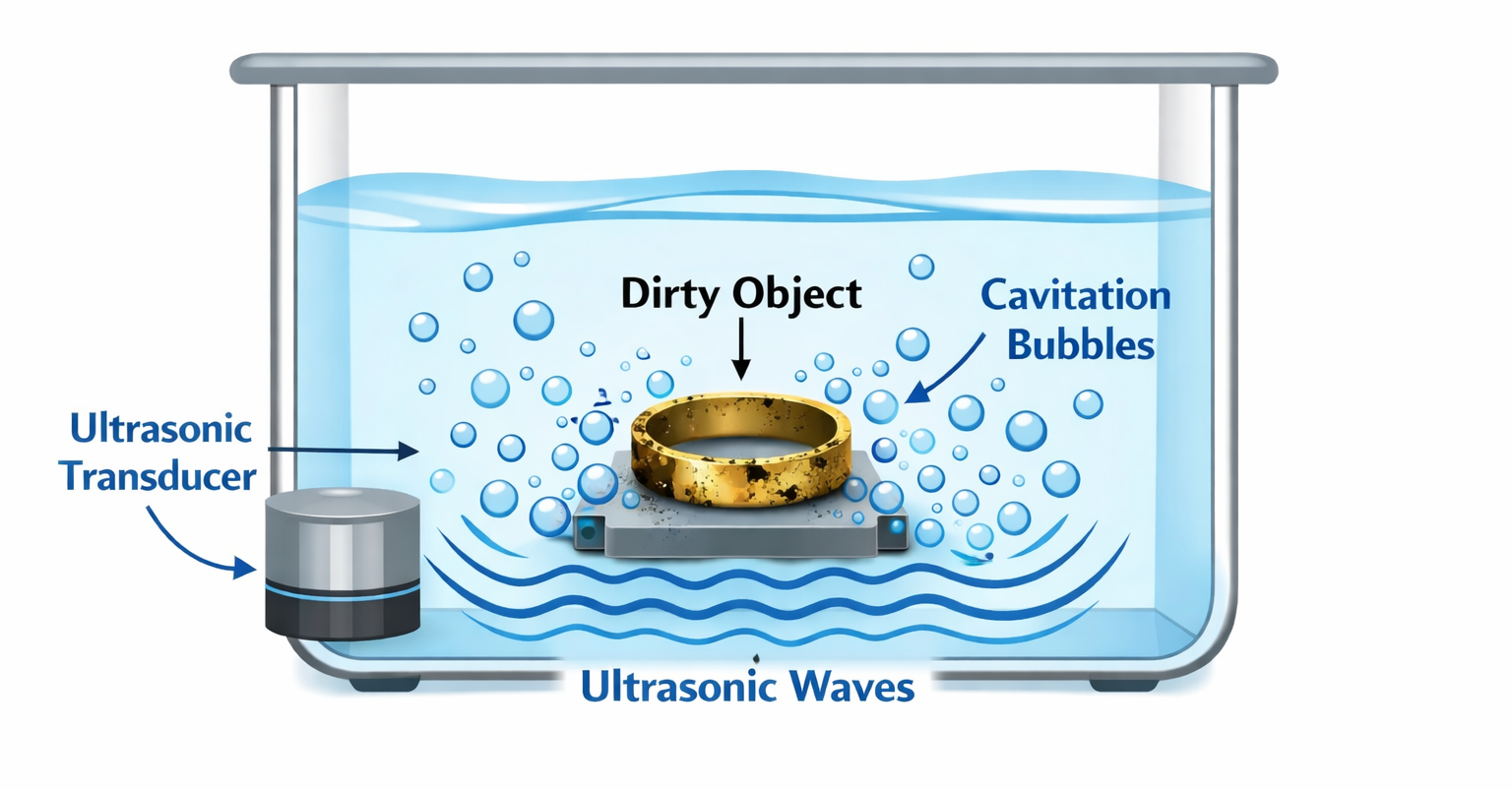

Ultrasonic cleaning uses very high frequency sound waves. These waves are far above what the human ear can hear. When they travel through a liquid, they create millions of tiny bubbles. This process is called cavitation.

These bubbles grow and then quickly collapse. When they collapse, they release small bursts of energy. These bursts are strong enough to loosen dirt, oil, and grime from surfaces, even in the smallest of gaps.

What Happens Inside the Tank?

Sound Waves in Action

The object being cleaned sits in a tank filled with liquid.

Devices called ultrasonic transducers are fixed to the inside of the tank to create and send sound waves through the liquid at high speed, usually at 20 to 40 kHz.

These vibrations are what form the microscopic bubbles. The bubbles are invisible to the naked eye, but they are extremely powerful at a small scale. They can reach and clean places that brushes simply cannot.

The Role of the Cleaning Liquid

The liquid is usually water mixed with a mild detergent. The detergent helps break down oils and grease. It also helps the bubbles form more easily.

Different materials may need different cleaning fluids. For example, metal tools may use a stronger mix, while delicate items such as electronics need a gentler solution. The right liquid makes a big difference in results.

Common Uses

Many industries depend on ultrasonic cleaning because it saves time and reduces labour. It is widely used for washing:

- Metal components and machine parts

- Medical instruments and surgical tools

- Electronic components

- Aerospace parts

- Automotive parts

These items often have small holes, grooves, or threads, which are hard to clean. Ultrasonic systems reach them easily.

Is Ultrasonic Cleaning Safe?

Yes, ultrasonic cleaning is safe when used correctly. The process is gentle on most materials. However, certain soft stones, fragile coatings, or thin plastics may need special care.

It goes without saying, but operators must also follow safety guidelines. Although the sound waves themselves are not harmful, direct contact with the liquid during operation is not recommended. Proper training will help to prevent these issues.

How Long Does the Cleaning Process Take?

An ultrasonic parts washer usually takes 3 to 20 minutes per cleaning cycle.

Typical Time Ranges

- Light dirt or dust: 3-5 minutes

- General grease and oil: 5-10 minutes

- Heavy carbon, thick grease, or burnt residue: 10-20 minutes

- Very complex or badly soiled parts: up to 30 minutes or more

Why Businesses Choose Ultrasonic Washing Systems

For companies that deal with precision parts or high volumes of equipment, ultrasonic cleaning offers clear advantages. It reduces manual effort, lowers the risk of damage, and produces repeatable results.

It also supports better hygiene and quality control. Clean parts perform better and last longer. In industries where even tiny particles can cause problems, this level of cleaning is essential.

Talk To Us Today

If you’re ready to upgrade your cleaning process or want to explore what an ultrasonic washing system can do for your business, simply get in touch with us on 01543 224608 and we’ll be happy to discuss your needs. Or email us at washers@unitech.uk.com. Our team is here to guide you, answer your questions, and help you find the perfect industrial washing solution.