COVID 19 has raised public awareness of the need to sanitise and adopt best practices to maintain a clean environment in which to work and socialise. It may be a shock to most, but some of these controls have been operated in the food industry for many years. The two general areas within a food facility (low risk and high care), and the transfer of goods and personnel between the two has always been an important control point. However, there is also the risk of transfer of bacteria and pathogens into the facility from outside sources, such as transport of raw materials and packaging.

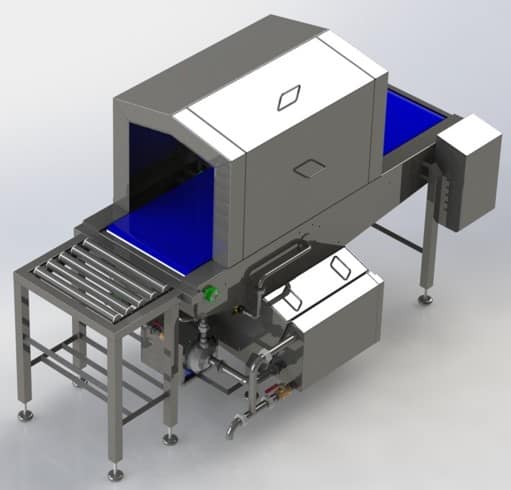

In order to alleviate the risks of products potentially transferring bacteria and organisms between areas and facilities, it is normal practice to introduce a sanitising tunnel, which attempts to kill any harmful bacteria at point of entry. Attempt? Yes that is correct – ‘attempt’, as there are several different systems and machines on the market that offer themselves as sanitising tunnels, but like most things in life there are good and bad systems out there. In the following points we are going to discuss several areas, where some sanitisers are not as good as you may think, and what Unitech Washing Systems offer to overcome some of these issues.

Sanitising Processes – UV Sanitising

There are 2 main processes for sanitising products, and both have their advantages. UV sanitising is a non-chemical and non-thermal cost effective system. It is excellent in situations where products are affected by aqueous chemicals and have to remain dry during the process, however the main issue with this method is that the light can only sanitise correctly where there are no shadows, which can sometimes be difficult when dealing with packaging and complex shapes. In addition to this, the residence time within the tunnel is dependent on the power of the lamps used and can be a lengthier process than aqueous sanitising.

Aqueous Sanitising

Aqueous sanitising is where the items pass through a curtain of liquid, which covers the product as it passes. The advantage of aqueous sanitisers is that the solution remains on the product for a period of time after exiting the tunnel, ensuring that the chemical has suitable time to take effect. It also means that the residence time within the system is greatly reduced.

It is important that when supplying a unit, consideration needs to be taken for various things such as the product being handled, water usage and chemical usage. The makeup of the item which will be sanitised can dictate whether it needs to be sanitised with a mist spray or a re-circulated flush system. For example, a larger jet size on a re-circulated system may be too much pressure for delicate items.

Mist Sanitisers

Mist sanitisers tend to be one shot units, where water and chemicals are mixed, sprayed over the product and then allowed to flow to drain. This type of unit is generally the cheaper priced of the 2 options of machines offered, and due to fresh water being used, the jet size and flow can be quite small, minimising the water and chemical usage.

Re-circulated Sanitisers

Re-circulated sanitisers are initially charged with the water and chemical mix, and re-circulate the solution with a pump. Filters are used to remove particulates that may come from the products, and higher flow jets can be used to deluge the water over the item to be sanitised. This is usually ideal for items such as ingredient tubs, packaged cheese blocks etc. Replenishment of the sanitising solution is automatic, as when the solution is carried out on the product (and the reservoir level eventually reduces), it is topped up from the mains via a proportional doser, which allows the correct mix of sanitising solution into the reservoir water supply. With a re-circulated sanitising tunnel, the water and sanitising fluid usage is generally a fraction of that of a one-shot mist sanitiser – making them a cheaper option in the long term.

Types of Sanitising Conveyor Systems

In either of the above options, products are loaded onto a conveyor belt in the ‘Low Risk’ area, and are transported through the spray jets into the ‘High Care’ area. This is where a high quality conveyor design can affect the efficacy of the process.

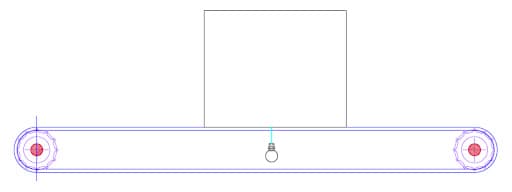

PU Belt Conveyors

If the conveyor is a solid PU belt (which is used in some basic units), the product may only be sanitised on the upper surfaces, leaving the base unaffected. An argument for this can be that the belt itself is wetted, so the product base does come in contact with the solution – but this depends on the package design, and on some ingredient buckets this would not be the case.

Modular Open Belt Designs

So, what about modular open belt designs? This type of belting is certainly more suited to the sanitising process, allowing fluid to be sprayed through the belt, and onto the base of the product, basically giving a 360° flow. However certain areas of the product can still be shielded from the flow of solution by the parts of the belt that are in contact with the product base. This method is employed on many units available on the market today.

In order to be certain of full coverage, it is recommended that belt contact is removed from the product in order to allow an uninterrupted flow of solution to all faces. This can be achieved in 2 ways. Firstly, by either having 2 conveyor belts, or by having a conveyor design that removes the belt and then re-introduces it following the spray bar – see Figure 2.

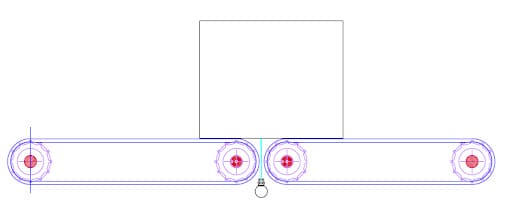

2 Belt Conveyor Systems

A 2 belt option means that the ‘High Care’ conveyor belt does not enter the ‘Low Risk’ area. It can also facilitate a bi-directional operation, allowing packaging or other items to be transferred back to the ‘Low Risk’ area in a controlled manner, isolating the fluid flow in the reverse operation. With the 2 belt system, a counter drive is used, by the means of a chain or meshing sprockets, which on some sanitisers can in itself introduce an additional issue when it comes to cleaning the unit.

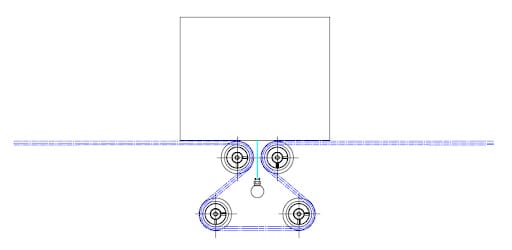

Divert Belt Design – Our Choice

With the Unitech Washing Systems divert belt design, a single belt system can be employed which allows for a full 360° coverage. This eliminates a counter drive (for one directional units), and improves the cleanability of the machine. It also sanitises the belt on the return, with the re-circulated units fully immersing the belt into the reservoir ensuring a completely sanitised belt is offered to the product at the infeed. – see figure 3.

Other Considerations

There are several other issues to be considered in the design of sanitising systems. For instance when transferring from a ‘Low Risk’ to a ‘High Care’ area, there may not be an operator to receive the product at the end of the process. Therefore it is important that a photocell or sensor is employed, stopping the conveyor belt to prevent goods either ending up on the floor (or if a physical stop is used), preventing the product from continually rubbing on the belt.

The cleanability of the units, ease of maintenance and hygienic construction are also important, and are often overlooked or compromised on many systems worldwide. The above points demonstrate there can be several differences between a well engineered, specifically designed sanitising unit, and a unit that performs the task inadequately. Employing the correct unit and principles can ensure your facility remains free of pathogens and bacteria that could easily be unintentionally introduced from outside sources.

Get In Touch

For more details on the Unitech Washing Systems sanitising units or on any other of our wash plants, please contact us and we would be more than happy to discuss any applications that you may have.